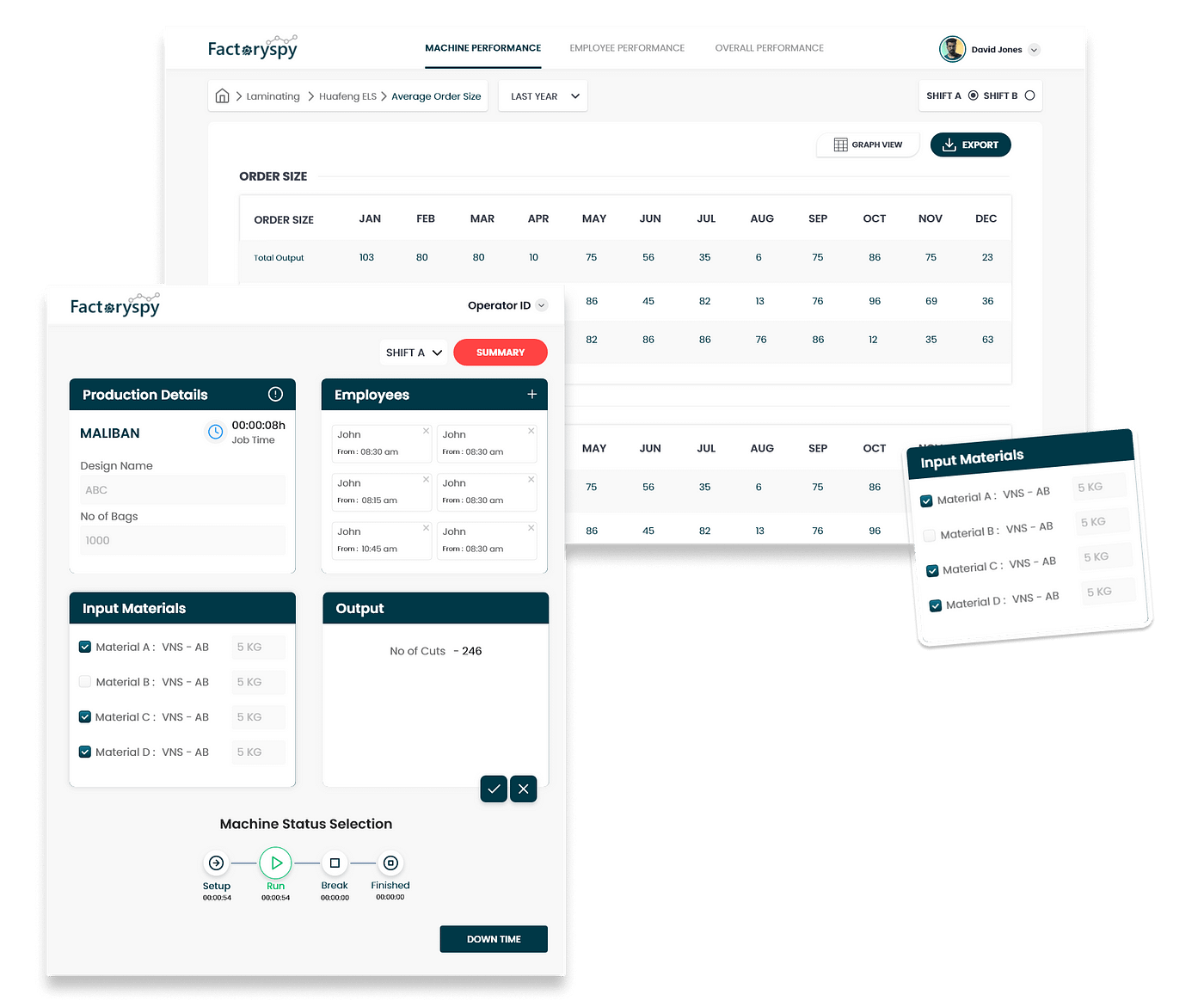

Data Visualization & Reporting

Automatically generate reports on a daily basis regarding the machine performance.

Real - time Monitoring

Our solution monitors your factory machines 24/7 to assure good quality and quantity.

Proactive Maintenance

Receive timely notifications concerning downtime and fluctuations in your machinery.